|

MEDIA

|

PROJECTS

|

SVO / WVO

(Straight vegetable oil / waste vegetable oil)

|

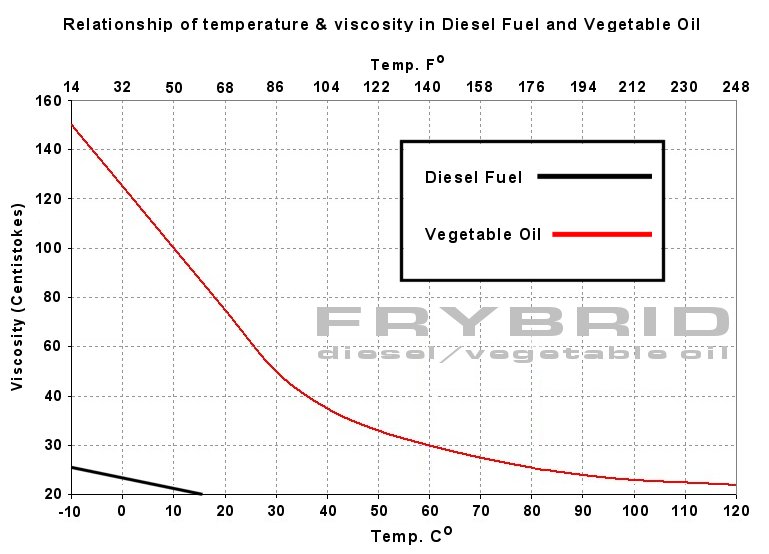

THEORY As we know the original Diesel engine was designed to run on vegetable oil, modern engines have however been designed to burn Petroleum Diesel fuel. This creates several issues which must be overcome in order for a modern engine to efficiently burn vegetable oil. Basic diesel engine theory can be found HERE Modern engines are fitted with injection systems designed to deliver and properly atomize diesel fuel which has a viscosity of approx.. 8 centistokes, vegetable oil is nearly 12 times as viscous (thick) and trying to spray it through an injector designed for a fluid so much less viscous is similar to trying to spray butter through a Windex bottle. An improper spray pattern will result in incomplete combustion, incomplete combustion will result in carbon deposits being formed in the engine which will destroy the engine. There are several ways to reduce the viscosity of vegetable oil, the simplest is through thermal degradation, as you can see from the information presented in Table 1, when vegetable oil has been heated to 160F its viscosity is very close to that of petroleum diesel.

The other issue which needs to be dealt with is the polymerization of vegetable oil when it contacts metal below an optimum temperature. The simplest way to explain this is with a simple analogy: If you place a pan on the stove, pour a small amount of vegetable oil in the pan and turn the heat to high. The pan will begin to heat up and as it does it will heat the oil, eventually it will reach 570F and begin to boil and begin to vaporize, the oil will burn and form carbon which will stick to the pan and destroy it. Now put out the fire, open all the doors and windows and allow the air to clear. Go to the cabinet and choose another $200.00 LeCrusette pan, place this on what is left of your stove and turn the heat on high again. When the pan gets to about 600F throw a tablespoon of oil in the pan, just before it bursts into flame singeing whatever is left of your eye brows, you will notice that the oil is skittering around the pan on a layer of vapor, none of the oil is sticking to the pan and none of it is turning to carbon. This same principle applies inside the combustion chamber of your engine, so injecting oil at any temperature into the combustion will result in carbonaceous deposits being formed on the piston crown and cylinder walls again destroying your engine. We now have two

major problems to overcome: Since we have an engine which is cooled with coolant (50% Distilled water, 50% Ethylene Glycol) we have an abundance of coolant which has been heated to 180F by the time the engine is up to operating temperature, we have a ready heat source. Since the engine must be at has an operating temp of 180F we have met the requirements set by problem #2 (engine at temp), and by using a coolant to fuel heat exchanger with the coolant being 180F we can easily produce fuel at above 160F meeting the requirements of problem #1. So we will need to have a vehicle with two independent fuel systems, one for Diesel (or Biodiesel) and one for the vegetable oil. We will start the vehicle on diesel fuel and run it on that fuel until we are at operating temperature, at this point we can supply vegetable oil at better than 160F and can switch the fuel supply. Of course when we shut the vehicle down the fuel system will still be filled with vegetable oil, which will cool and become useless as a fuel prohibiting us from restarting the vehicle as the conditions to solve problems 1 & 2 are no longer being met. To solve this issue we will need to purge the vegetable oil in the fuel system with diesel before we shut the engine off. Several manufacturers have developed systems which enable the use of vegetable oil in a diesel engine, however under inspection I found them all lacking on one or all areas required for a functioning vegetable oil fuel system. The most common error I discovered was that nearly every system relies on a small inefficient heat exchanger in the fuel tank to provide all the heat to bring the vegetable oil to injection temperature. One such system was installed in a VW Diesel pickup I owned, the round tank was installed in the bed under a canopy. On a 55F day I drove for 45 minutes in traffic, the engine came to temperature quickly, but the temperature gauge I had installed in the tank had barely moved, after 45 minutes it read an oil temp of only 120F. I realized that the previous owner had driven for thousands of miles injecting oil at no more than 120F (just for comparison, your residential water heater is usually set to 140F). It became obvious to me that simply heating the tank with a coil and running the vegetable in a PEX fuel line inside a coolant line was not enough heat. In addition this system was being required to heat the full volume of the fuel tank to injection temperature. This meant that each time I drove I had to heat 15 gallons of fuel to 160F before I could use any, perhaps helpful on a cross country trip but of little use in the city. I also discovered that many of the systems on the market routed the unused fuel back into the inlet side of the injection pump so that they did not have to run a return line back to the fuel tank. While this meant that the heated fuel was not sent back to the tank (which needed to be at injection temperature anyway) it also meant that in order to purge the fuel system, the fuel in the lines, injectors and injection pump had to be consumed in order to be replaced with diesel fuel before shutdown. In addition because it was a closed system and diesel could only be introduced as the vegetable oil in the system was consumed, this volume of fuel was only slowly being diluted with the incoming diesel so that the entire volume of fuel not only needed to be consumed once, but 6 times to insure that no vegetable oil was present, this led to very long purge times and a proclivity to trap air in the fuel system resulting in fuel system failure. Some systems went as far as to simply permanently "Loop" both the diesel and the vegetable oil which is a particularly poor idea as diesel is a poor lubricant to begin with and when heated becomes a destructive force in the fuel system, this is why most diesel engine actually have a fuel cooler in the return line. I then set out to redesign a system from the ground up. I took each component separately and designed each to exceed its system requirements. We need the following components to have a functioning vegetable oil fuel system which will not result in engine damage: 1) A tank to contain the vegetable oil. It should be constructed to the same specifications as the fuel tanks used in race cars. The tank should have an internal baffle to prevent the fuel from sloshing from side to side. It should be constructed from a material which will not react with the vegetable oil it contains. The area around the fuel pickup tube should be heated to insure that the fuel is thin enough to be drawn through the fuel lines without undue restriction. 2) Fuel lines to supply fuel to the engine and return unused fuel to the tank should be heated to thin the fuel enough to be drawn through the lines without undue restriction. 3) A fuel filter. This will also need to be heated so that the fuel can be filtered easily, in addition the filter itself should be an easily replaced part and readily available. 4) A final fuel heat exchanger capable of using engine coolant to heat fuel to the required temperature at maximum fuel flow. 5) Switching valves to switch between the two fuel systems. These should be independently controlled so that no cross contamination of fuel takes place and to speed the purging of fuel from the system. 6) A controller to switch the valves when the fuel is at the proper temperature and not before, to provide status indicators (Diesel mode, VO mode) to the driver, to provide an alarm if the vehicle is shut down while running on vegetable oil and to control the purging function so that the driver need minimal interaction and can devote his or her attention to driving as this is, after all, the point of the exercise. What I came up with and subsequently developed is a system built to the highest quality, utilizing materials and components from the automotive, racing and aviation industries. Each component far exceeds its design requirements and is in most cases far better designed than the fuel system in the vehicle. The FRYBRID System has raised the bar in this new field far above the level of any other system, each and every component is state of the art. I continue to research better materials and methods and constantly keep a vigilant eye on others in the field to insure that the FRYBRID System remains on the cutting edge. A complete FRYBRID system explanation can be found by clicking the system tab at the top of this page or on the FRYBRID link also located at the top of the page. |